Electrical Discharge Machining

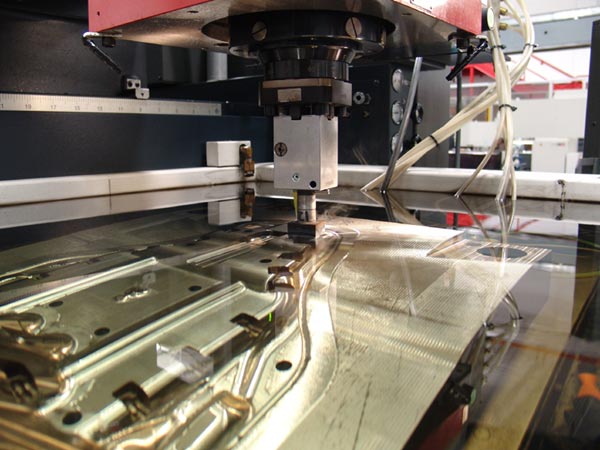

An Electrical Discharge Machine

Electrical discharge machining (EDM), also known as spark machining, spark eroding, burning, die sinking, wire burning or wire erosion, is a manufacturing process whereby a desired shape is obtained by using electrical discharges (sparks).[1] Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the “tool” or “electrode,” while the other is called the work piece-electrode, or “work piece.” The process depends upon the tool and work piece not making actual contact.

When the voltage between the two electrodes is increased, the intensity of the electric field in the volume between the electrodes becomes greater than the strength of the dielectric (at least in some places), which breaks down, allowing current to flow between the two electrodes. This phenomenon is the same as the breakdown of a capacitor (condenser) (see also breakdown voltage). As a result, material is removed from the electrodes. Once the current stops (or is stopped, depending on the type of generator), new liquid dielectric is usually conveyed into the inter-electrode volume, enabling the solid particles (debris) to be carried away and the insulating properties of the dielectric to be restored. Adding new liquid dielectric in the inter-electrode volume is commonly referred to as “flushing.” Also, after a current flow, the difference of potential between the electrodes is restored to what it was before the breakdown, so that a new liquid dielectric breakdown can occur.

Source: https://en.wikipedia.org/wiki/Electrical_discharge_machining

Electrical Dischage Machine News

SST, a global distributor of machine tool and consumable brands, held a ribbon-cutting ceremony October 30, 2017, to officially open its new facility in New Britain, Connecticut. The facility will serve as the company’s EDM consumables headquarters, enabling SST to better reach manufacturers seeking machine tools and EDM supplies, and to offer greater product diversity, including the full line of Makino machine tools.

Dating back to 1995, Global EDM Supplies forged its relationship in the New Britain community. Following the merger of Global EDM Supplies and SST, the opportunity exists to grow the history, leadership and established philosophy around the consumables business within the region and beyond, according to SST.

“Global EDM Supplies has deep roots in New Britain, and with that comes strong customer relationships and an experienced employee base that we wanted to sustain and grow. Even though we have a new name and new facility, we are the same people dedicated to fueling the manufacturing industry within this region,” says Tom Kucharski, Consumable Sales and Operations Manager.

The 40,000-square-foot space is set to open November 18 and is designed to house the combined workforce of SST Consumables and Global EDM Supplies, including the service, application, sales and operation departments. Additionally, a Makino showroom is incorporated into the facility for machine demonstrations and training, along with an ample warehouse to ensure product availability and quick delivery.

Source: https://www.mmsonline.com/news/sst-opens-new-edm-consumables-facility-in-connecticut